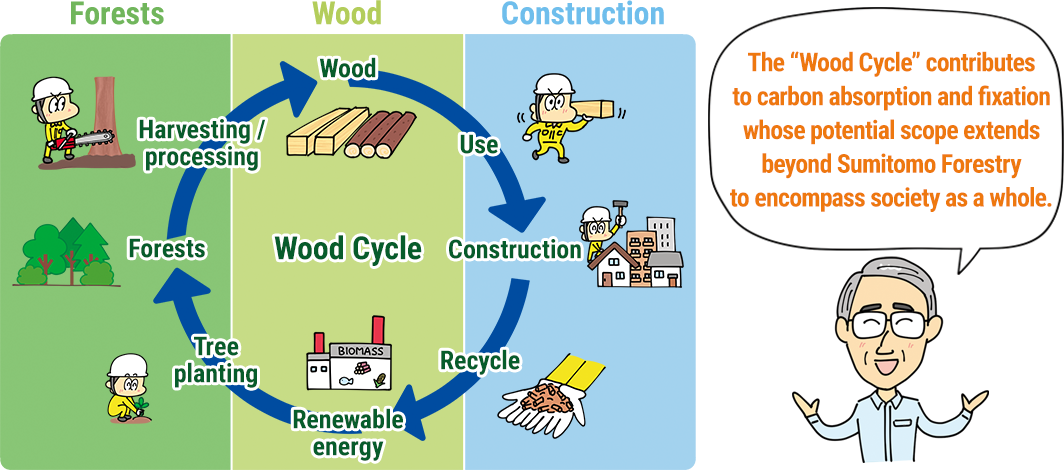

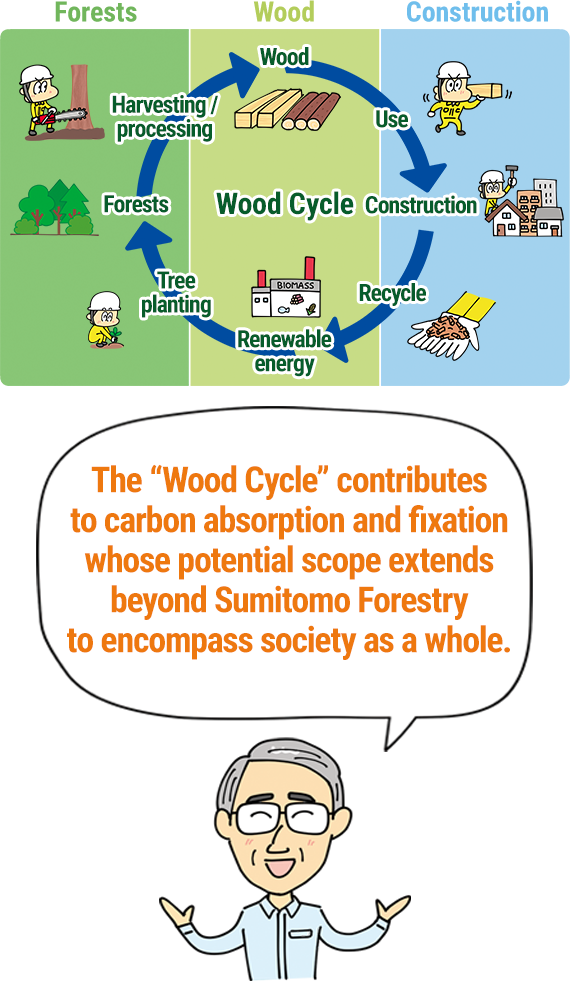

I approach the building, which is situated amid abundant flourishing greenery. Stepping inside, I find myself in a spacious gallery whose wooden walls are configured in a distinctive checkerboard pattern. This is the extraordinary new research building of Sumitomo Forestry’s Tsukuba Research Institute, one of a handful of research centers in the world focused exclusively on trees, timber and all the amazing things you can do with wood. “Sumitomo Forestry’s entire business is based on the Wood Cycle, our name for the value chain centered on wood. We plant, cultivate and harvest trees; use timber and timber-derived building materials in construction of durable buildings; and use waste wood and unused wood for biomass power generation. We are one of the only companies exclusively devoted to maximizing the value of trees and timber throughout its business,” says Mr. Ichiro Nakajima, Supervisory Officer Chief Engineer of Sumitomo Forestry Tsukuba Research Institute, who showed us around.

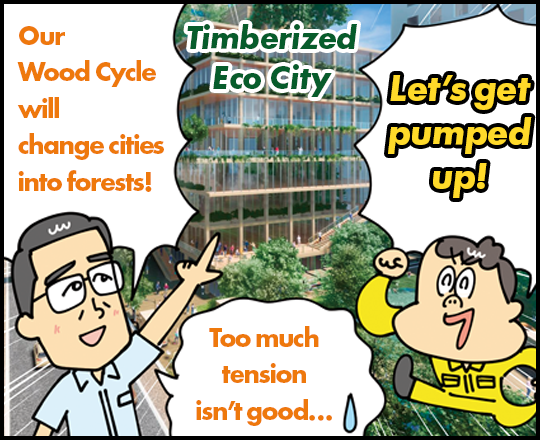

Sumitomo Forestry traces its history back to 1691, when the Besshi Copper Mines opened in what is today Niihama, Ehime Prefecture, and harvesting of timber from adjacent forested mountain slopes for use as fuel for smelting and as mine props began. Fast forward to 1894, the year Sumitomo launched the Great Reforestation Plan to restore the mountain slopes ravaged by excessive logging and smoke pollution. “Developing business while protecting the environment is second nature to us. This is the Sumitomo Forestry spirit. It motivates us and is a source of pride throughout the company,” says Mr. Nakajima. The Timberized Eco City concept embodies this philosophy. Forests are carbon sinks, absorbing lots of CO2 from the atmosphere through photosynthesis. “As wooden construction spreads, the city will emulate the forest as a carbon sink. So, we are in the business of changing cities into forests. Here, this fine new building is our base where we pursue research and technological development to create an environmentally friendly timber-utilizing city,” says Mr. Nakajima.

For example, strong timber from sturdy trees is needed to construct robust buildings. This is where genomic selective breeding comes in. Whereas conventional selective breeding takes many years, the institute is accelerating the process by developing trait prediction models for the selection of elite trees, which are fast-growing and superior in material quality, through extraction and analysis of genetic information at the seedling stage. Sumitomo Forestry has been applying tissue culture cloning technology since 2000 to ensure the preservation of rare tree species, such as the weeping cherry trees at Daigoji Temple in Kyoto City, where Toyotomi Hideyoshi, a feudal lord who completed the 16th-century unification of Japan, held cherry blossom viewing parties. Other R&D themes that the Tsukuba Research Institute is tackling include material processing methods, earthquake and fire resistance of buildings, and environmentally friendly biodegradable plastics derived from wood.

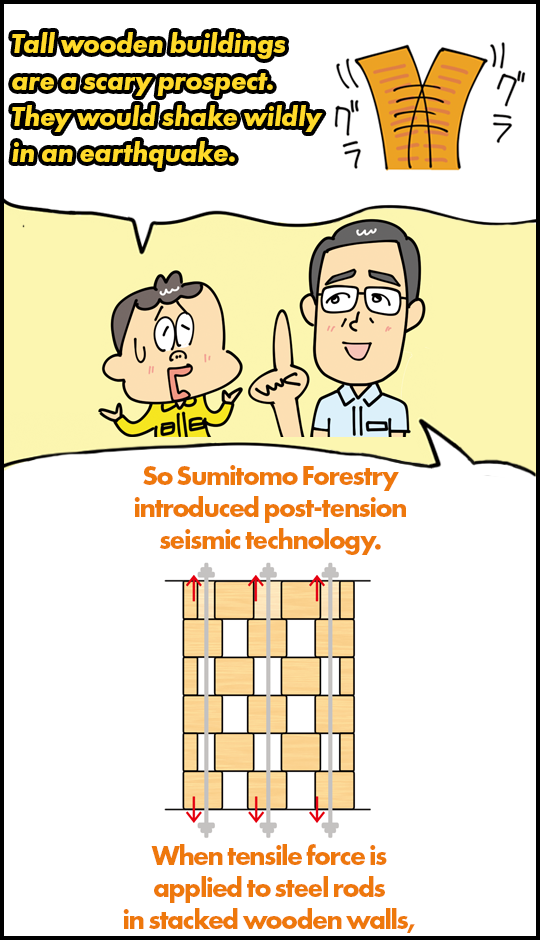

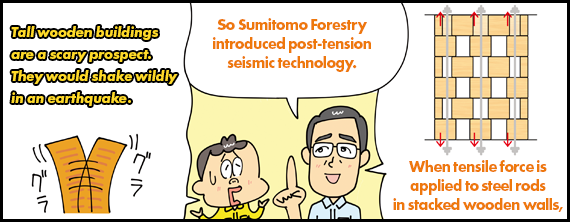

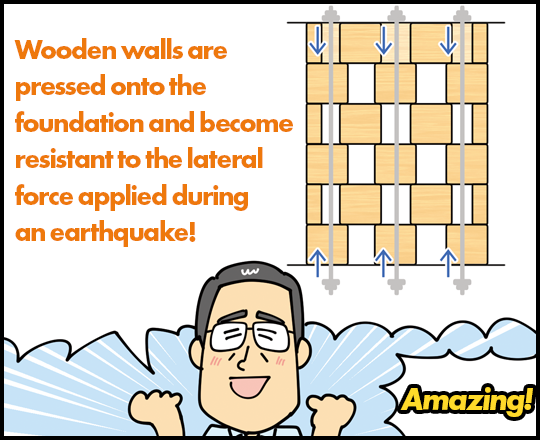

The orientation of Tsukuba Research Institute’s research is set out in the W350 Plan, a research and technology development roadmap geared to realizing a Timberized Eco City in 2041, coinciding with the 350th anniversary of the foundation of Sumitomo Forestry. The W350 Plan is now integrated into the Mission TREEING 2030 long-term vision. As well as being an R&D center unlocking the tremendous value inherent in wood, the new research building is also a venue for lots of ingenious experimentation, as revealed by Mr. Nobutaka Isoda, Team Manager of the Planning Group. The gallery’s checkerboard walls use post-tension seismic technology, a new technique for supporting med- to large-scale wooden constructions. Steel rods are threaded through the wall posts and tightened to increase resistance to lateral forces applied during earthquakes. The new research building is a three-story wooden structure, but its height of over 15 meters is equivalent to that of a typical five-story building. The new technology is employed for technical verification so as to open up the possibility of med- to large-scale wooden constructions. “This technology is already applied in Building No. 15 at Sophia University in Tokyo,” Mr. Isoda explains. In terms of energy utilization, the company envisages zero energy buildings (ZEBs) that make optimum use of natural light and natural ventilation and use wood fuel for heating and cooling.

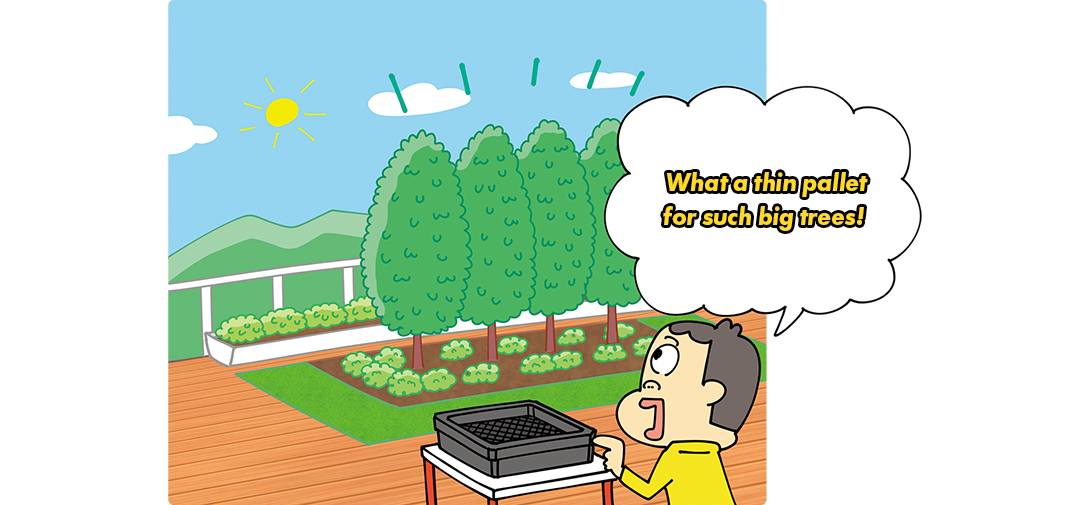

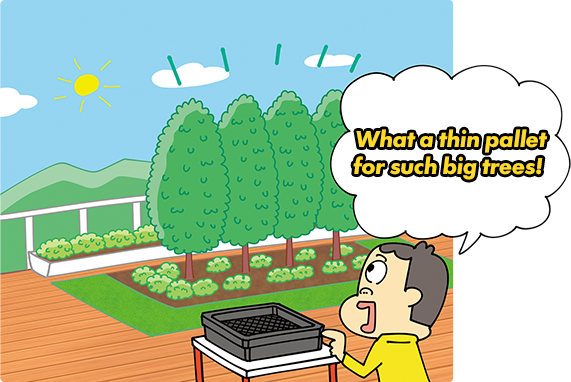

This lush vegetation with its profusion of fresh green leaves delights the senses but is also here for experimental and verification purposes. Specially designed louvers are installed in the skylight as part of a system calibrated to the latitude and longitude of Tsukuba City, where the institute is located, to ensure optimum exposure of the plants to sunlight, supplemented, as necessary, with light from LEDs. As well as evaluating the growth of plants under various conditions, the study also encompasses psychological and physiological aspects, such as the effects of an environment rich in greenery on workers. Meanwhile, in the rooftop garden, a rooftop greening system designed to withstand strong winds is being evaluated. The trees are over 2 meters tall, yet the soil is a mere 15 centimeters in depth at the shallowest point! They are grown on a two-layer pallet consisting of a thin band of soil and a water reservoir. The institute is developing greening technology for tall buildings, taking into consideration wind, irrigation, solar radiation, and waterproofing. Next to the garden is a two-tone wooden bench. A protective coating developed by the institute that maintains the texture of the wood and prevents deterioration has been applied to one side of the bench. The difference between the side with the coating and that without is evident at a glance. In the foyer overlooking the rooftop garden, attractive curvilinear panels suspended from the ceiling appear to float in space. “Exhibited at Milan Design Week, this is a simple way of exploiting the attributes of wood, for example to improve concentration and induce relaxation. We are conducting demonstration tests in actual office spaces,” says Mr. Isoda.

“Maximizing the value of forests and wood to realize decarbonization and a circular bioeconomy” is a key policy of Mission TREEING 2030, Sumitomo Forestry’s long-term vision announced in 2022. I felt that the research and technological development conducted in this new research building will indeed breathe new life into Japan’s forestry industry, promote the use of wood in cities, and eventually lead to the emergence of a circular economy and the decarbonization of society.

EN

EN