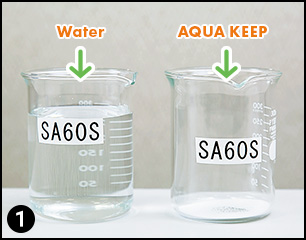

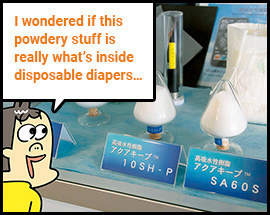

As a father of two children, I am certainly familiar with disposable diapers for babies and infants. Super absorbent polymer holds urine to prevent leakage. I recall watching a video clip of a demonstration illustrating the absorption performance of disposable diapers: a diaper absorbed at least half a liter of water poured from a plastic bottle. So how is this magical material produced?

To find out, we visited Himeji Works of Sumitomo Seika Chemicals where AQUA KEEP (AK for short) super absorbent polymer is produced. From the image associated with sanitary products, I was imagining an uncluttered white space with powdery absorbent resin supplied through glass tubes. But first, outside under the hot midsummer sun, I was shown four gigantic tanks. They contain acrylic acid, the principal raw material of AQUA KEEP.

Himeji Works produces about 200,000 tons of AQUA KEEP a year. This is where all the acrylic acid used in the production of AQUA KEEP is stored. Hence the scale of this tank farm. The acrylic acid is transported to Himeji Works by ship. Overlooking the Seto Inland Sea, Himeji Works has a salty maritime atmosphere.

“Acrylic acid is a difficult chemical to handle. If temperature control isn’t done properly, a chemical reaction called natural polymerization may occur, leading to ignition. No other company in Japan has huge tanks for acrylic acid like ours,” explains Mr. Hideshi Tanigawa, General Manager of Himeji Works. I had no idea that if you trace the humble disposable diaper back to its origins, you will find yourself in a world of complex, potentially hazardous, chemical processes.

Since this a chemical plant, there is plenty of complicated piping routed around the site. Acrylic acid is supplied to the AK Facility, where AQUA KEEP is produced.

“Himeji Works started making the forerunner of AQUA KEEP back in 1983, and the oldest facilities date back to that year. Ever since, spurred by growing demand for disposable diapers, we have been adding new facilities. Demand soared in the 1990s. In the 21st century, the pace has quickened with a new facility coming on stream every couple of years and the facilities themselves getting bigger, reflecting the expansion of demand,” explains Mr. Manabu Fujiwara, Manager of the General Affairs and Personnel Office.

Until the mid-1980s, consumers tended not to regard disposable diapers as run-of-the-mill everyday products but instead used them when doing something special, such as going on a trip. But they have become commonplace products viewed as daily necessities. The expansion of the AK Facility at Himeji Works reflects this history. “Demand for disposable diapers is still on a steep upward trajectory, centering on China and developing countries. Given these circumstances, our business will likely experience further expansion in the future.” (Mr. Fujiwara)

EN

EN