Believe it or not, I studied some architecture at high school. Although my dabbling in architecture is long past, my affinity with cement may be a legacy of my youthful studies. Indispensable for roads, railways and all sorts of other infrastructure, cement is actually a very environmentally friendly material. I visited the Tochigi Plant of Sumitomo Osaka Cement to find out what cement making is all about.

The principal raw material of cement is limestone. Kuzuu in Sano City where Tochigi Plant is located has long been known for its rich limestone deposits, which have been quarried since the Edo period. Indeed, limestone from Kuzuu was used for repairing Edo Castle. With a feeling of nostalgia induced by all this history, I arrived at our first destination: Karasawa Mine. At the mine, where limestone has been quarried for some 80 years, production is currently

running at about 3 million tons per year.

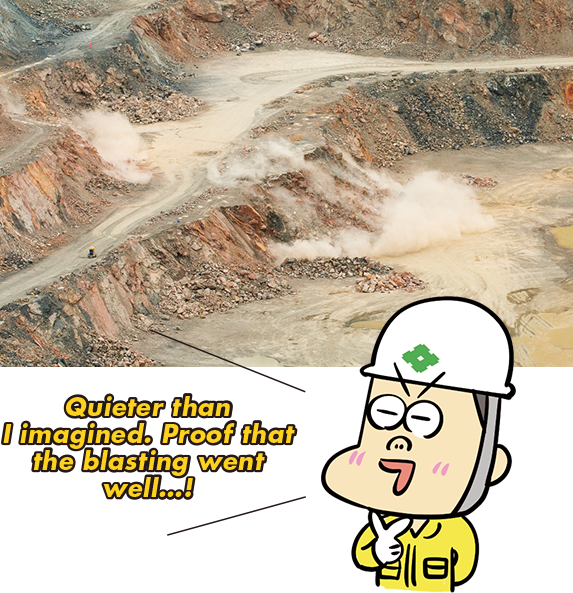

At the entrance of the mine is a gigantic 90-ton dump truck. Its massive tires are 2.7 meters in diameter. Encountering this behemoth at the start of the tour fuels my excitement. The terraced slopes are typical of an opencast mine. Quarrying using the bench-cut method results in this memorable topography. Look back on the way to the top of the hill for a panorama reminiscent of Machu Picchu. What a spectacular view!

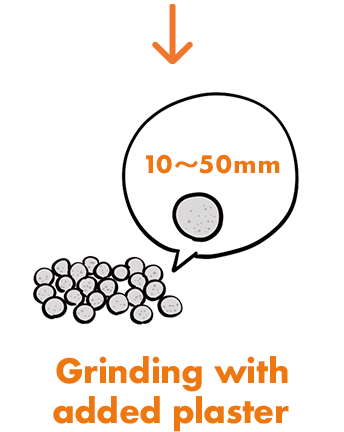

But our main purpose in visiting the mine is not just run-of-the-mill sightseeing. We are here to experience blasting, the highlight of activity at the mine. Dynamite loosens up more than 10,000 tons of limestone in a split second. Blasting is done at Karasawa Mine once a day, always at 11:50 a.m. The clock is ticking. I hold my breath... Bang! There is an almighty rumbling and trembling. At that moment, there is a tremendous upheaval in the bedrock in the direction I was told to look. It collapses like a mountain of sand. But as I approach, it is evident that these are not grains of sand but rocks, many too large for me to shift even if I summon all my strength to the task. Step by step, these rocks will be crushed into smaller pieces until the largest are no more than 90 millimeters in diameter. Then they are transported to the plant.

The rocks are whisked to the plant by the Capsule Liner, which is unique to this mine. Compressed air is used to propel capsules containing limestone at 32 kilometers per hour through a 3-kilometer pipeline to the plant at a rate of 300 tons of limestone per hour. I imagine small trucks running through the pipeline. It looks like something from science fiction. In fact, the system was originally conceived and designed in the Soviet Union.

EN

EN