Illustrator Ryoko Takagi visits Sumitomo Group

Tohoku Sumiden Precision

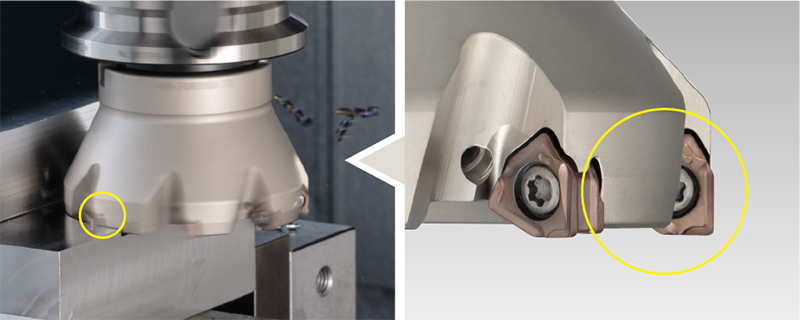

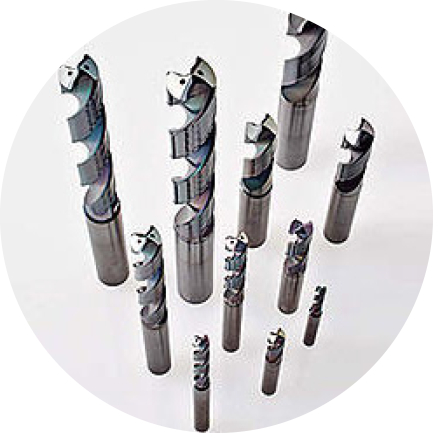

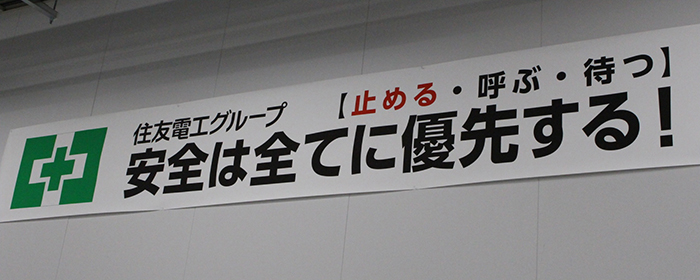

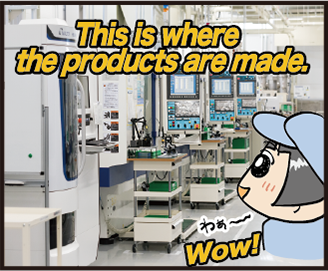

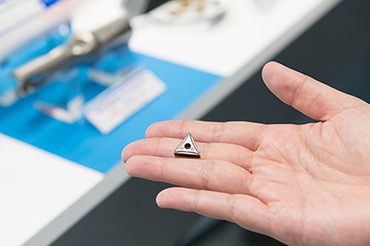

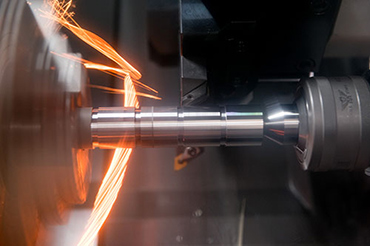

The principal site of Sumitomo Electric Hardmetal, a manufacturer of IGETALLOY carbide tools such as carbide drills and milling cutters, in Miharu-machi, Fukushima Prefecture. The company’s stirring slogan is “Flourish with people: From Miharu to the world!”

EN

EN