Traffic accidents can destroy people’s lives in an instant. Besides falling asleep at the wheel, factors related to the drivers’ health, such as poor physical condition, sudden onset of illness, and exhaustion attributable to overwork, are implications of the growing proportion of traffic accidents. Sumitomo Riko is developing a driver monitoring system (DMS) that employs sensors, for which its proprietary flexible and conductive rubber material is applied, to detect the driver’s health condition and drowsiness.

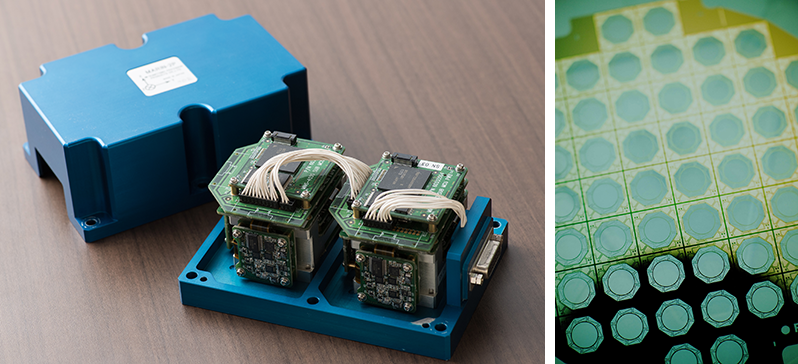

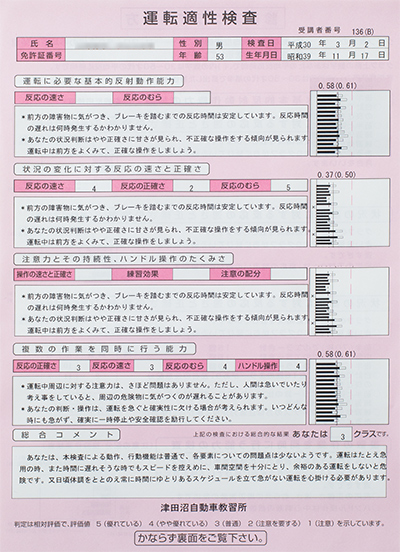

The DMS capitalizes on the attributes of Sumitomo Riko’s proprietary Smart Rubber (SR) Sensor that is built into a cushion placed on the driver’s seat. The sensor detects the pressure distribution and its change and vibration from bones in the buttocks and estimates the pulse rate, respiration rate, and shift in center of gravity based on a unique algorithm. The results are transmitted to the cloud for use in various services, such as issuing of alerts and implementing measures to keep the driver awake. Conventional conductive rubber is generally hard and conductive paths tend to break when it is stretched. By adopting elastomer that is soft and conductive, Sumitomo Riko developed SR with the ability to withstand repeated stretching and compression which means that conductive paths are maintained. Having confirmed that SR can be utilized for sensor electrodes, Sumitomo Riko tackled development of applications for safe driving. For measurement of vital signs, subjects typically have to wear cumbersome sensor devices and are reluctant to do so. As the SR Sensor is soft and causes no discomfort, the driver simply needs to be seated on the DMS for vital sign measurement.

EN

EN One-point explanation

One-point explanation