In earthquake-prone Japan, the frequent occurrence of destructive earthquakes is a vivid reminder of the country’s seismic vulnerability. How best to prevent the collapse of buildings and infrastructure, and thus ensure the sustainability of communities, is a question that has long exercised the minds of people in Japan.

The head office and the factory of Sumitomo Rubber Industries in Kobe suffered considerable damage in the Great Hanshin-Awaji Earthquake of 1995. This experience strengthened the company’s resolve to contribute to the development of communities resilient to natural disasters. Leveraging the rubber technology the company had cultivated, principally through the development of tires, ever since its establishment, Sumitomo Rubber Industries released MIRAIE, a vibration control system for houses, in March 2012.

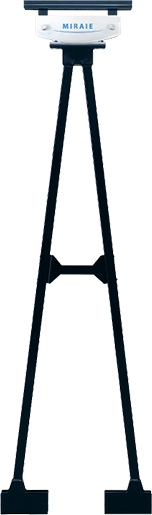

In terms of seismic countermeasures for houses, the mainstream approach had long been to endow them with “earthquake resistance” by strengthening the building’s structure to make it resistant to tremors. This approach, however, may be ineffective in the event of a powerful earthquake of 7 on the Japanese seismic intensity scale and collapse is a distinct possibility if repeated aftershocks occur. Meanwhile, “seismic isolation,” technology to keep tremors from reaching a building, became a focus of attention in the 1990s, but high cost prevented its widespread application to houses. Rather than earthquake resistance or seismic isolation, Sumitomo Rubber Industries focused on “vibration control” to absorb tremors, developing high-damping rubber that converts the kinetic energy of tremors into thermal energy. Capable of absorbing 95% of the vibration of an earthquake, MIRAIE has already been applied to 44,000 houses across Japan, achieving an outstanding track record of zero collapses due to earthquakes.

The vibration control technology of MIRAIE is also protecting important cultural properties, such as Goei-do (Founder’s Hall) and Otani Mausoleum at Higashi Honganji Temple in Kyoto. For Higashi Honganji, the restoration project’s target is durability for the next 200 years, which Sumitomo Rubber Industries expects its vibration control technology to satisfy.

The vibration control technology of MIRAIE is being used in the restoration of the keep of Kumamoto Castle. The Kumamoto Earthquake of 2016 was the first in Japan for which scale 7 tremors were recorded twice. Despite the earthquake’s destructive power, none of the 132 MIRAIE-equipped houses near the epicenter collapsed or suffered major damage.

Noting the impressive performance of MIRAIE, Obayashi Corporation, the contractor for the Kumamoto Castle keep restoration project, approached Sumitomo Rubber Industries and decided to adopt MIRAIE technology for the castle keep.

For historic buildings such as castles, temples, and shrines, the vibration control structure should be inconspicuous, so as not to compromise the aesthetic appeal of the architecture, and not impede the flow of visitors. In view of these constraints, Sumitomo Rubber Industries’ compact and lightweight vibration control dampers are ideal. They are also low-cost and require no maintenance for a long time. These advantages proved decisive in the decision to install MIRAIE for the top floor of the large keep in 2018 and for that of the small keep in 2019. MIRAIE will continue to support the integrity of Kumamoto Castle, the glorious symbol of the region, far into the future.

Sumitomo Rubber Industries intends to promote the application of vibration control technology for historic structures since if such traditional buildings sustain severe damage, their repair and restoration poses great challenges in terms of both technology and cost. Moreover, the company is receiving an increasing number of inquiries from other earthquake-prone countries. Going forward, Sumitomo Rubber Industries relishes opportunities to endow buildings with resilience to disasters while also contributing to sustainable regional development.

EN

EN One-point explanation

One-point explanation