Sumitomo Osaka Cement Co., Ltd. is developing innovative technologies for carbon dioxide capture, utilization and storage (CCUS) in order to achieve our carbon neutrality vision “SOCN 2050”.

Sumitomo’s Connection with Expos

Sumitomo Osaka Cement

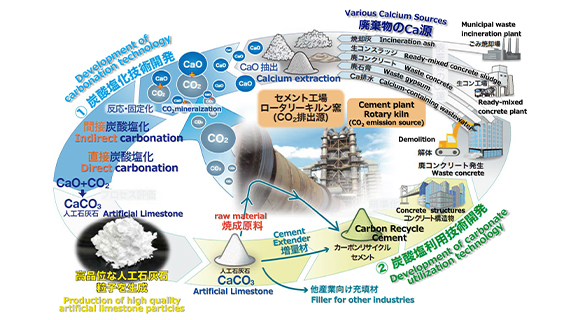

Sumitomo Osaka Cement Co., Ltd. is developing innovative technologies for carbon dioxide capture, utilization and storage (CCUS) in order to achieve our carbon neutrality vision “SOCN 2050”.

Sumitomo Osaka Cement Co., Ltd. has developed a “dual recycling technology for calcium and CO2” that combines calcium contained in waste with carbon dioxide to produce the CO2-recycled artificial limestone* and fix CO2 as a mineral.

For more information about Sumitomo Osaka Cement’s carbon neutrality technology, click here. (in Japanese)

The concrete curbs installed around the Sumitomo Pavilion use approximately 500 kg of CO2-recycled artificial limestone which has fixed approximately 210 kg of CO2. This fixed amount is among the highest in the world, and there are great expectations as a technology to prevent global warming.

Sumitomo Osaka Cement Co., Ltd. is also advancing initiatives to utilize CO2-recycled artificial limestone in various industries beyond cement and concrete, where calcium carbonate has traditionally been used.

At the goods sales corner of the Sumitomo Pavilion, you will find stationery made from paper and resin incorporating CO2-recycled artificial limestone.

We are delighted to be using the world’s first CO2-recycled artificial limestone, a technology that holds great promise for achieving carbon neutrality in the construction sector, at Expo 2025. We hope that visitors to the Sumitomo Pavilion from around the world will learn about this innovative technology.