Social Issues addressed by Sumitomo —Compass for the Future—

Recycling disaster waste to assist recovery of stricken areas

Decarbonization

Decarbonization Supply

chain

Supply

chainJapan is prone to earthquakes and the incidence of extreme weather events, notably typhoons, seems to be increasing as a consequence of climate change. By proactively accepting and recycling waste generated by natural disasters, Sumitomo Osaka Cement is helping establish a circular economy that is highly beneficial to society.

In a country prone to natural disasters, swift disposal of the enormous quantities of waste generated by these events speeds recovery but poses a major challenge for the stricken areas. Eager to address this issue, the Sumitomo Osaka Cement Group accepts disaster waste at its five cement plants around Japan, recycling it as raw materials used in cement production and as a source of thermal energy for the production process.

Cement plants in Japan are notable for their minuscule emissions of waste during the production process. The cement producers operate their plants based on a policy of minimizing waste. To give some perspective: of the approximately 550 million tons of waste generated each year in Japan, the volume of landfill attributable to the cement industry is no more than 500 tons.

As a matter of policy, Sumitomo Osaka Cement started proactively accepting disaster waste in 2011 when the Great East Japan Earthquake struck. In principle, similar to general waste, disaster waste should be treated within the municipality where the waste is generated, such as by incineration at local waste incineration plants. Treatment of waste that cannot be treated within the municipality is outsourced. But the massive quantities of waste generated by the Great East Japan Earthquake dwarfed the waste treatment capacity of local governments in the stricken areas. Responding to the crisis, Sumitomo Osaka Cement accepted about 100,000 tons of disaster waste, consisting of rubble and other debris.

In subsequent years, the company established a track record of accepting disaster waste, including 8,000 tons of stockpiled rice and tatami mats ruined when the Kinugawa River overflowed its banks in 2015 at Joso City, Ibaraki Prefecture, as a consequence of torrential rain in the Kanto and Tohoku regions; 18,000 tons of wood scraps generated by the earthquakes in Kumamoto Pre-fecture in 2016 from the prefectural government and Kumamoto City; 1,000 tons of wood scraps in the wake of Typhoon Lionrock in 2016 from Kuji City, Iwate Prefecture; 40,000 tons of wood scraps and other debris generated by heavy rains in western Japan in 2018; and 28,000 tons of assorted debris—wood scraps, tatami mats, rice straw, etc.—in the aftermath of Typhoon Hagibis in 2019. The plants of Sumitomo Osaka Cement consumed all this disaster waste.

Sumitomo Osaka Cement’s acceptance of disaster waste is a contribution to society. By maximizing the positive impacts of its cement plants on neighboring communities, it is the company’s earnest desire that local residents will appreciate and cherish the plants, viewing them as beneficial to their communities. The group has five cement plants (Hachinohe, Tochigi, Gifu, Ako, and Kochi) across Japan. In principle, the plants close to disasteraffected areas proactively accept disaster waste.

To handle disaster waste, plants have to restrict acceptance of other types of waste so as to secure treatment capacity. Waste must also be sorted and when, as is sometimes the case, this has to be done manually, the waste treatment cost may become relatively high.

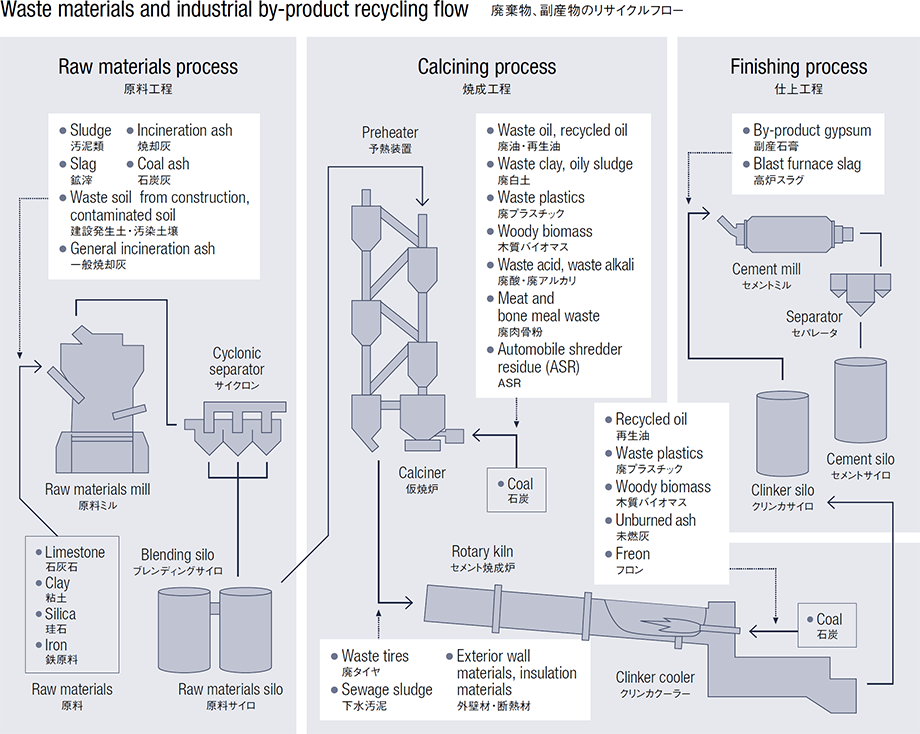

Cement production consists of three principal processes: the raw materials process, the calcining process, and the finishing process. Disaster waste is used in the raw materials and calcining processes. The main ingredients of cement are calcium, which is abundant in the Earth’s crust, silicon, aluminum, and iron. Previously, limestone was used as a source of calcium, and clay as a source of silicon and aluminum. All these ingredients can be replaced by waste or by-products. Substitutes for aluminum include coal ash, waste soil from construction, and contaminated soil, whereas silicon can be replaced by casting sand.

Substitutes for coal as a source of thermal energy in the calcining process include waste oil, woody biomass, and waste plastics. Disaster waste, consisting of assorted debris such as wood scraps, sodden tatami mats, spoiled stockpiled rice, and rice straw, is accepted and recycled as raw materials and a source of thermal energy. All the ash produced in the calcining process is used as raw materials. Since calcining is a high-temperature process performed at around 1450oC, generation of harmful substances, such as dioxins, is suppressed.

To ensure preparedness in the event of a natural disaster, the Sumitomo Osaka Cement Group is concluding agreements with local governments on treatment of disaster waste so as to expedite acceptance of disaster waste. Having such agreements is reassuring for local governments since they know Sumitomo Osaka Cement is ready and able to swiftly respond to requests to accept disaster waste at its plants whenever the need arises.

In cooperation with local governments, Sumitomo Osaka Cement will support the recovery of disaster-stricken areas by swiftly accepting disaster waste, and moreover, will contribute to society by producing cement using recycled disaster waste, large quantities of which will be used in the construction of infrastructure to prevent or mitigate the effects of natural disasters.

Read about initiatives to achieve a low-carbon society, aiming at net-zero greenhouse gas emissions since these emissions are implicated in global warming.

In view of ongoing globalization and the growing complexity of supply chains, companies need to respond appropriately to issues in supply chains.

The pace of workstyle reform is accelerating as the COVID-19 pandemic has prompted numerous companies to embrace novel ways of working.

For companies, the COVID-19 pandemic has brought the crucial importance of employee health into sharp focus.

Accelerating global warming poses serious business risks. Accordingly, companies need to formulate strategies and implement specific countermeasures from a medium- to long-term perspective.

Spurred by efforts to reduce environmental impacts and in line with increasing social needs, replacement of gasoline-powered vehicles with electric vehicles is accelerating.

Vigorous initiatives are afoot to tackle social issues by revitalizing communities and the interpersonal relationships that bind them together.

Poverty persists in contemporary Japan and the existence of child poverty is a grave concern.

In view of the continuing decline of Japan’s working age population, due to population aging coupled with a low birthrate, development of the next generation is an urgent issue.

The rapid progress in medicine in recent years is largely due to the efforts of not only universities and other research institutions but also of companies to develop cutting-edge technologies.

Numerous initiatives to promote industry and commerce at the regional and community level are underway, involving the use of renewable energy and thus contributing to decarbonization.

One-third of food produced is lost or wasted globally, amounting to about 1.3 billion tons per year. Food loss and waste is a pressing issue in need of a solution.

Companies are addressing a wide range of issues so that people and companies can coexist in harmony with the global environment.

In addition to natural disasters, there are various types of hazards whose nature, incidence and severity are changing with the times. Resilience and flexibility are indispensable in dealing with them.

Read about initiatives to achieve sustainable regional revitalization. The attributes and resources that each region can offer are leveraged to strengthen local economies and overcome the problem of population decline.