Social Issues addressed by Sumitomo —Compass for the Future—

Leveraging core competency in polymer materials technology to drive automotive electrification and spur progress toward carbon neutrality

Decarbonization

Decarbonization Electrification of mobility

Electrification of mobilityThe electrification of mobility, led by the electrification of automobiles, is essential for a sustainable society. Historically, Sumitomo Riko’s core business has been the manufacture of anti-vibration rubber, hoses, and other components for automobiles powered by internal combustion engines. With the progress of electrification, however, the value of these core products may decrease, or they may no longer even be required. Such developments would have major implications in terms of business continuity.

Sumitomo Riko established the Advanced Automotive Systems R&D Center in 2016 with a mission to develop new fundamental products geared to the needs of the CASE (Connected, Autonomous, Shared & Services, and Electric) era. In order to promote R&D transcending the boundaries of existing business units, multiple development organizations were integrated to form the Advanced Systems R&D Center in 2020.

Sumitomo Riko embarked on product development focusing on A, autonomous driving, and E, electrification, among the four elements of CASE, leveraging its core competency in polymer technology for rubber and other materials. The company’s initiatives have an important bearing on decarbonization, as is well illustrated by Finesulight, a high-performance thin-film thermal insulation material commercialized in 2020.

The greatest drawback of the current crop of EVs is limited range. One way of extending range, thus enhancing utility and peace of mind, is to reduce the amount of electricity consumed for purposes other than driving. Such an approach corresponds to the nature of EVs: since they do not have an internal combustion engine to serve as a heat source, they consume substantial amounts of electricity, for example, to heat the vehicle interior in winter, which reduces their range.

Sumitomo Riko excels in thermal management using polymer materials. The company had long pursued R&D on heat dissipation and had already commercialized heat dissipation materials for application in vehicle motors. However, to reduce the amount of electricity consumed for purposes other than getting from A to B, heat must be used effectively without letting it escape. So, turning the conventional approach on its head, the company began R&D on thermal insulation in 2016.

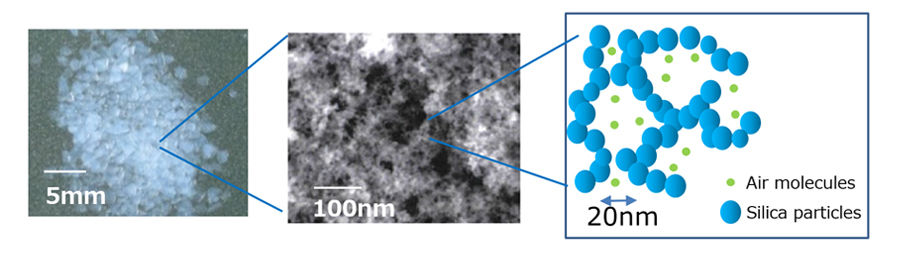

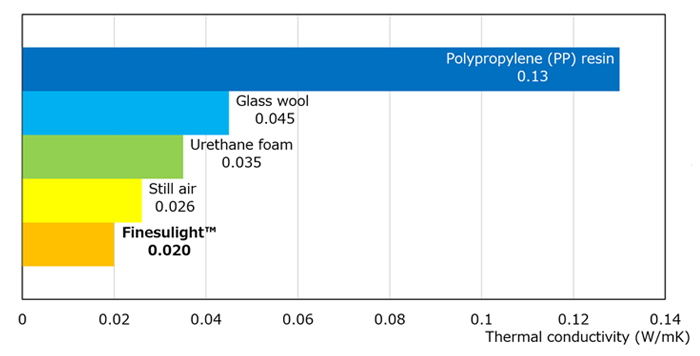

This led Sumitomo Riko to home in on silica aerogel. There are lots of different thermal insulation materials, but the company concluded that something more sophisticated than those currently available was needed in order to use heat effectively in EVs. Thanks to a novel structure with numerous nanopores so miniscule that air convection is precluded and thermal conduction suppressed, silica aerogel’s thermal insulation properties are truly outstanding. But it does have some drawbacks: silica aerogel is a hard-to-handle fragile powder that is not easily soluble in water, which makes it difficult to commercialize as a thermal insulator.

Relishing the challenge, Sumitomo Riko came up with the idea of turning silica aerogel into a coating liquid to make it easier to handle. Although the powdery substance does not mix well with water, the company proceeded by trial and error while leveraging its sophisticated polymer materials technology, eventually achieving a silica aerogel coating that it commercialized as Finesulight.

In addition to its impeccable thermal insulation properties, Finesulight is thin, light, and flexible, and moreover, is usable in a wide temperature range, extending from low to high. Therefore, it is applicable to various components of EVs, whether pure EVs or plug-in hybrid vehicles (PHVs/PHEVs), to effectively block the inflow and outflow of heat. This translates into substantial gains in terms of efficient use of electricity, which will not only help extend range but also improve comfort inside the vehicle while enhancing passenger safety in the event of an emergency such as a vehicle fire. Over and above these benefits, the promotion of electrification of mobility will lead to reduced CO2 emissions and spur progress toward carbon neutrality.

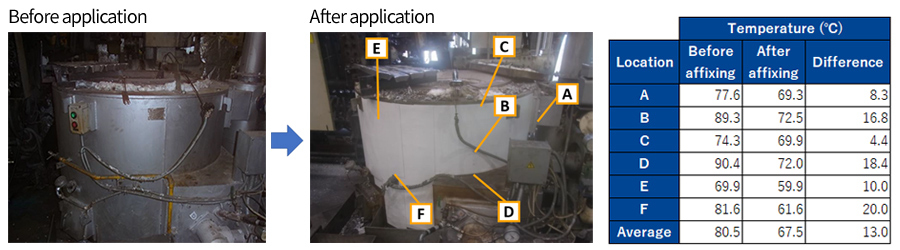

Furthermore, the possible uses of Finesulight are by no means limited to mobility, though that is of course a massive application field. For example, it can be used to curb the energy consumption of factory equipment, thus reducing CO2 emissions. Although various exhaust heat countermeasures are implemented at factories in Japan, reflecting the progress of energy-saving initiatives, further improvements are needed to achieve carbon neutrality. Updating factory equipment is costly, requiring much time and effort. On the other hand, Finesulight is available in sheet form as a general-purpose product that, affixed to existing equipment, suppresses exhaust heat. To cite just one case of good practice at a factory, Finesulight is applied to a high-temperature aluminum holding furnace for die casting to reduce the surface temperature of the furnace, thereby saving energy, improving the working environment, and enhancing safety as an additional burn-prevention measure.

The use of Finesulight for other applications has started. For food delivery services, which have experienced growing demand during the COVID-19 pandemic, Finesulight is applied to the pads placed at the bottom of delivery bags to keep food warm. Finesulight is also used in portable freezer boxes for transporting COVID-19 vaccine at a constant temperature and for coolers for outdoor use. By virtue of its properties as a high-performance thin-film thermal insulation material, Finesulight can be used without changing the design of the delivery bags or boxes, thus offering outstanding convenience.

Mindful of the changes sweeping through society, which are transforming lifestyles as well as mobility, Sumitomo Riko is mounting an effective response, including through organizational reform. Transcending the boundaries of business units, the initiatives of the Advanced Systems R&D Center signal an organizational shift away from conventional product-out development toward a market-in approach. As for CASE, in the field of A (autonomous driving), the company is promoting sensing-related development by utilizing Smart Rubber, a material embodying its prowess in rubber technology. Sumitomo Riko intends to continue offering products and solutions leveraging its core competencies so as to help resolve pressing environmental and social issues, including but not limited to decarbonization and the electrification of mobility.

Read about initiatives to achieve a low-carbon society, aiming at net-zero greenhouse gas emissions since these emissions are implicated in global warming.

In view of ongoing globalization and the growing complexity of supply chains, companies need to respond appropriately to issues in supply chains.

The pace of workstyle reform is accelerating as the COVID-19 pandemic has prompted numerous companies to embrace novel ways of working.

For companies, the COVID-19 pandemic has brought the crucial importance of employee health into sharp focus.

Accelerating global warming poses serious business risks. Accordingly, companies need to formulate strategies and implement specific countermeasures from a medium- to long-term perspective.

Spurred by efforts to reduce environmental impacts and in line with increasing social needs, replacement of gasoline-powered vehicles with electric vehicles is accelerating.

Vigorous initiatives are afoot to tackle social issues by revitalizing communities and the interpersonal relationships that bind them together.

Poverty persists in contemporary Japan and the existence of child poverty is a grave concern.

In view of the continuing decline of Japan’s working age population, due to population aging coupled with a low birthrate, development of the next generation is an urgent issue.

The rapid progress in medicine in recent years is largely due to the efforts of not only universities and other research institutions but also of companies to develop cutting-edge technologies.

Numerous initiatives to promote industry and commerce at the regional and community level are underway, involving the use of renewable energy and thus contributing to decarbonization.

One-third of food produced is lost or wasted globally, amounting to about 1.3 billion tons per year. Food loss and waste is a pressing issue in need of a solution.

Companies are addressing a wide range of issues so that people and companies can coexist in harmony with the global environment.

In addition to natural disasters, there are various types of hazards whose nature, incidence and severity are changing with the times. Resilience and flexibility are indispensable in dealing with them.

Read about initiatives to achieve sustainable regional revitalization. The attributes and resources that each region can offer are leveraged to strengthen local economies and overcome the problem of population decline.